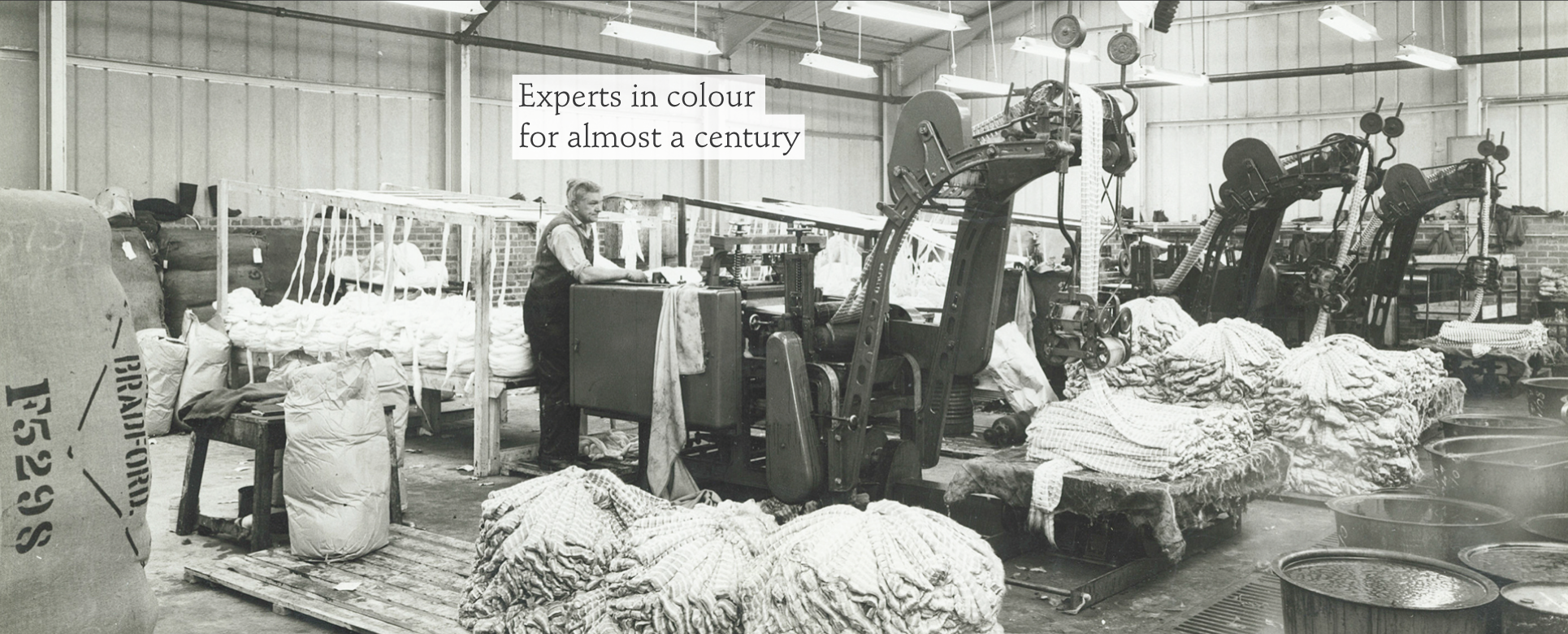

Yorkshire has long been famous as a centre for textiles and excellence in textile manufacture as the industrialists of the 19th century took advantage of the soft water supplies and growing wool and cloth trade. The origins of the present day Bulmer & Lumb Group lie in an offshoot of the Smith Bulmer spinning company, managed by Sir William Bulmer, based in Holmfield, Halifax. The company opened a dyehouse there in 1920, to enable them to concentrate on spinning coloured yarns.

The company continued to grow throughout the 1930s and 40s, and Bulmer & Lumb acquired an excellent reputation for coloured worsted spun yarns. During these years, as demand for UK manufactured textiles increased, the company bought a number of other mills across Bradford and the wider area.

Trading off its Top Dyeing expertise the company began producing coloured tops for both home and overseas markets, which continues to be an important part of the business. As the business grew plans were made to construct a new single storey site at Buttershaw.

Work began on the 42 acre site in 1957, and in 1960 dyeing started at the new purpose built mill that the company still occupies today.